- OFFERTE

-

Riscaldamento

Riscaldamento Prity

- Stufe a Legna Prity

- Termostufe a Legna Prity

- Stufe a Legna con Forno Prity

- Termostufa a Legna con Forno Prity

- Stufe a Legna in Ghisa Prity

- Cucina a Legna Prity

- Termocucina a Legna Prity

- Camini a Legna Prity

- Inserti Camini Prity

- Termocamini a Legna Prity

- Inserti Camini Ventilato Prity

- Camini in Ghisa Prity

-

Canne Fumarie

- Serbatoi per acqua

- Serbatoi Accumulo

-

Pezzi di Ricambio

- Riscaldamento Centrale

- Cucina

- Home

- Installazione

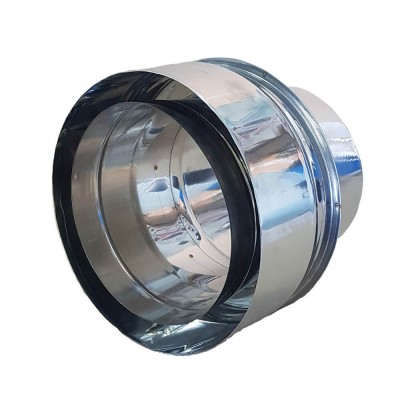

- Riduzione Canna Fumaria

- Riduzione Canna Fumaria, Acciaio Inox AISI 304, Ф300M-350F

Riduzione Canna Fumaria, Acciaio Inox AISI 304, Ф300M-350F

€ 53,03

Della stessa marca

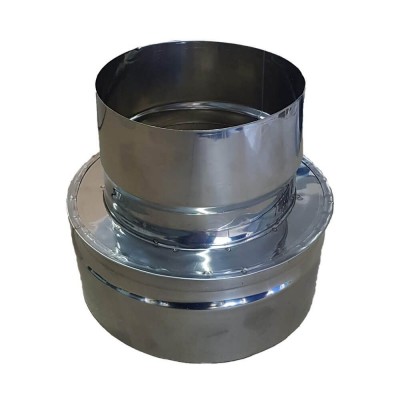

l sistema fumario mono parete tradizionale offre grande praticità nel montaggio, grazie alla perfetta calibratura ottenuta tra l'innesto maschio e fem..

€ 31,03

Imponibile:€ 25,85

l sistema fumario mono parete tradizionale offre grande praticità nel montaggio, grazie alla perfetta calibratura ottenuta tra l'innesto maschio e fem..

€ 49,64

Imponibile:€ 41,37

l sistema fumario mono parete tradizionale offre grande praticità nel montaggio, grazie alla perfetta calibratura ottenuta tra l'innesto maschio e fem..

€ 53,59

Imponibile:€ 44,66

l sistema fumario mono parete tradizionale offre grande praticità nel montaggio, grazie alla perfetta calibratura ottenuta tra l'innesto maschio e fem..

€ 59,23

Imponibile:€ 49,36

l sistema fumario mono parete tradizionale offre grande praticità nel montaggio, grazie alla perfetta calibratura ottenuta tra l'innesto maschio e fem..

€ 61,49

Imponibile:€ 51,24

l sistema fumario mono parete tradizionale offre grande praticità nel montaggio, grazie alla perfetta calibratura ottenuta tra l'innesto maschio e fem..

€ 64,87

Imponibile:€ 54,06

l sistema fumario mono parete tradizionale offre grande praticità nel montaggio, grazie alla perfetta calibratura ottenuta tra l'innesto maschio e fem..

€ 71,64

Imponibile:€ 59,70

l sistema fumario mono parete tradizionale offre grande praticità nel montaggio, grazie alla perfetta calibratura ottenuta tra l'innesto maschio e fem..

€ 76,15

Imponibile:€ 63,46

l sistema fumario mono parete tradizionale offre grande praticità nel montaggio, grazie alla perfetta calibratura ottenuta tra l'innesto maschio e fem..

€ 22,00

Imponibile:€ 18,33

Used for connecting flue pipes with different diameters. This model is specifically designed for pellet stoves with flue pipe diameter of 80mm an..

€ 10,55

Imponibile:€ 8,79

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 22,00

Imponibile:€ 18,33

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 22,00

Imponibile:€ 18,33

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 28,21

Imponibile:€ 23,50

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 28,21

Imponibile:€ 23,50

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 34,41

Imponibile:€ 28,68

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 36,67

Imponibile:€ 30,56

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 34,41

Imponibile:€ 28,68

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 36,67

Imponibile:€ 30,56

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 36,67

Imponibile:€ 30,56

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 36,67

Imponibile:€ 30,56

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 36,67

Imponibile:€ 30,56

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 36,67

Imponibile:€ 30,56

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 42,87

Imponibile:€ 35,73

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 42,87

Imponibile:€ 35,73

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 49,08

Imponibile:€ 40,90

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 49,08

Imponibile:€ 40,90

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 53,03

Imponibile:€ 44,19

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 22,00

Imponibile:€ 18,33

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 22,00

Imponibile:€ 18,33

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 22,00

Imponibile:€ 18,33

Used for connecting flue pipes with different diameters. Suitable for wood stoves, pellet stoves, and all kinds of central heating boilers (gas, oil, ..

€ 28,21

Imponibile:€ 23,50